Personal computers affected the way we work, 3D printers will affect the way we live

|

|

Once we build this house, everything will change... |

Can you imagine building a traditional home once you've seen the rounded corners, vivid colors, and smooth finishes on a 3D printed home?

Although most of the homes built today by giant

3D printers extrude only concrete and lack the resolution to print the house on the left, we are getting closer at a very fast rate. Multi-material print heads and specialized thick nozzle technology (a current project of mine) will open up the use of stucco, wood polymers, and plastics in addition to concrete. 3D printers are already printing with glass, PVC, and copper. Eventually, the plumbing and wiring will also be printed.

As a result of these amazing technologies, many current construction trades will no longer be in high demand. Those that are ready to adapt to the new methods however, will see amazing growth in the need for their services. I am committed to spread this word to as many of todays construction trades as possible so the same people can continue to do the same things they do well. |

|

|

| These hotel suites were printed entirely with a 3D printer |

|

| Ornaments like the crown trim on the top of the building and the awnings above the windows were simply added to the blueprints by the architect which are fed into the printers brain where the drawing is converted into mechanical actions by the printer. These functional enhancements can be added to a building at no additional cost for construction. |

|

|

|

Columns, crown moldings, and curved walls provide designers with options they have never had before |

| The impact will be dramatic and the new building and housing designs will make 3D printed architecture the preferred method of construction. Building costs will be cut by over 40% and the result will be structures that are sturdier, safer, more efficient, and better looking for less money. |

| |

|

|

| Your office building will grow and shrink as needed using lego-like pod connectors |

|

| Architects will create environments like the one you see here that can curve, snake, and grow as needed to accomodate odd shaped properties, personnel growth, contraction, or special project needs. |

| |

|

|

|

Aerodynamic design provides better weather shelter |

| Curved slopes and rounded edges allow high winds to pass over without damage to the structure. Single piece contruction makes 3D printed structures stronger than traditional method of laying block connected by concrete. |

| |

|

|

| This mansion estate in China was built entirely by a 3D printer. |

|

| Sections of this project were printed and then used to assemble the finished structure. (Sounds like cheating to me). |

| |

|

|

Todays 3D house printers are still works in progress but work is progressing fast

|

|

Caterpillar and SCG Concrete Materials to invest in 3D house printing project |

Professor Khoshnevis is by far the world's leading expert on 3D house printing, or "Contour Modeling" as it is also named. The printer shown here is his invention which represents some of the most advanced technology announcedat this time..

This project is being funded by both Caterpillar and SCG, a large Thai concrete materials company.. |

|

|

| This monster uses mud and clay o build houses in impovershed countries |

|

| A new Russian inventor created this massive 3D printer using 3 rod WASP technology to move the extruder head up, down, right, left, forward, and backward. Impressive as it looks, it adds no new capabilities over the other 3D House Printers. |

|

|

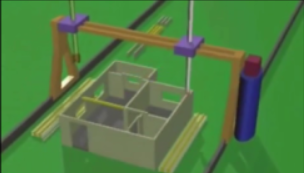

Click to view this 3D printer animation |

This animation shows how a 3D house is printed |

While you are watching, consider the simplicity of this printer working just like a bubble jet printer except instead of emitting ink which absorbs, it emits a thick fluid that starts out as a liquid and then hardens to a solid, such as concrete.

The animation shows how the printer begins from the ground up just spreading a thin layer of material that the concrete manufacturers have specially formulated to come out smooth and dry quickly. By the time one layer is applied, the previous layer has dried so it starts over doing the next layer of concrete.

|

|

|

| |

|